Last Updated on August 5, 2022

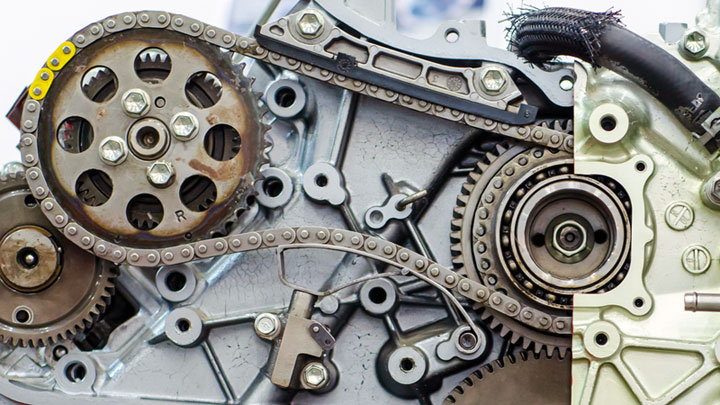

Before vehicle computers were invented, cars and trucks used a system of mechanical and pneumatic devices to manage systems such as valve timing and idle speed.

Now, modern vehicles have a complex system of sensors and actuators connected to computers which enable the vehicles to perform well and efficiently. These electronics are confusing enough without adding a bunch of acronyms that sometimes refer to the same thing!

Let’s start with a dictionary so we all know what is being referred to in this article.

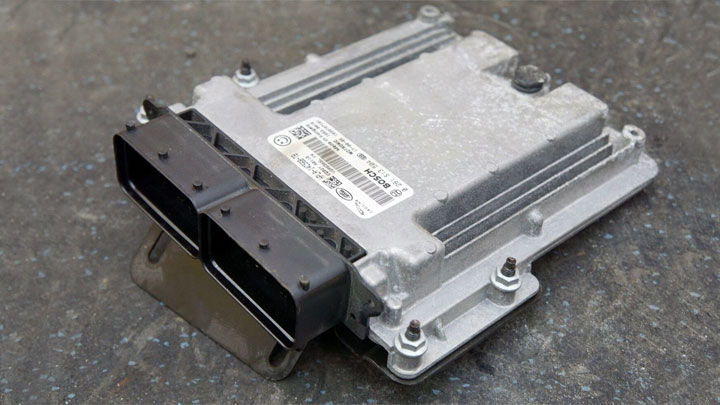

ECM (or ECU)

The engine control module is often known as the “brain” of the vehicle. This computer enables optimal engine performance and ideal emissions by controlling air, fuel, and spark.

The ECM works by taking in data from a variety of sensors throughout the vehicle and adjusting actuators to provide the appropriate response for the situation. It “decides” what response to give by the specific way it’s programmed by the manufacturer.

For this reason, vehicles cannot substitute different types of ECMs because the wrong kind may cause decreased performance or even failure to operate.

Variable valve timing, idle speed, ignition timing, fuel injection, emission control, cruise control, and theft protection are just some of the crucial things controlled by the ECM. The programming maps out exactly what needs to happen with each combination of numbers given by the sensors.

Some of these sensors bringing information through wires to the ECM are air-fuel sensors, oxygen sensors, MAF (mass air flow) sensors, camshaft and crankshaft position sensors (which allow the computer to calculate RPM and engine load), throttle position sensor, coolant temperature sensor, and the exhaust gas recirculation (EGR) valve sensor (for emissions information).

The ECM is so critical to the operation of the vehicle that at startup it goes through a systems check process. If any of the involved sensors disagree with the idle speed during this process, the vehicle gets put into limp mode.

This limits the amount of power the engine will deliver and often the gears you can use to avoid powertrain damage or dangerous situations caused by out-of-control speed.

See Also: DTC U0001, DTC U0073, DTC U1000 (CAN Bus Communication Issues)

TCM

The transmission control module is what allows the transmission in automatic vehicles to shift gears. Manual transmission vehicles don’t have this because the driver is the TCM.

Sensors in automatic vehicles send information to the TCM so that the transmission changes gears at the best time for ideal fuel efficiency and optimal engine performance.

Some sensors are the vehicle speed sensor, wheel speed sensor, throttle position sensor, turbine speed sensor, and transmission fluid temperature sensor.

There is a lot of information that can be sent from variable driving conditions to help the transmission adjust. Slope of the road, rate of acceleration or deceleration, and speed of the vehicle all affect which gear is best to be in at that moment (as manual drivers have learned).

Automatic transmissions often give the vehicle a smoother ride than manual transmissions, though of course it depends on the programming and on the driver respectively.

Related: DTC P0700 (Transmission Control Issue)

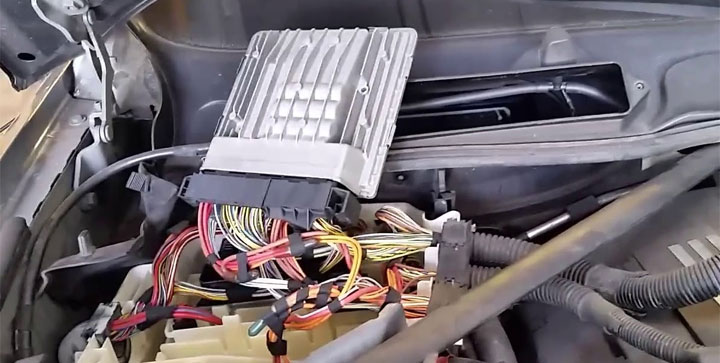

PCM

The powertrain control module controls the charging, emissions, and transmission systems of the vehicle. The powertrain refers to the engine, transmission, and driveline and is what gets the power from the driver’s throttle inputs to the wheels.

The PCM is essentially a bigger “brain” than the ECM, since it often includes the ECM itself and the TCM. All the sensors send data to the PCM and it responds by making adjustments for optimal engine performance and efficiency.

As these newer vehicles accrue miles, their computers “learn” how the machines operate to further increase efficiency.

The air-fuel ratio, RPM at which to shift, how brakes are applied with ABS (antilock braking system), emissions, charging system, variable valve timing, idle speed, ignition timing, fuel injection, exhaust system, electronic differential performance, and t are just a few of the things controlled by the PCM.

Sensors include those found in the ABS system, the check engine light, throttle position sensors, MAP (manifold absolute pressure) sensor, knock sensor, coolant sensor, and oxygen sensor. Several of these will overlap with sensors listed for ECM and TCM, since the PCM replaces both of those.

An important job of the PCM is to alert the driver to a problem by flashing codes or lights on the dashboard in a timely manner to prevent damage to the car.

See Also: Faulty Body Control Module Symptoms

Problems

Vehicle electronics can become damaged by corrosion (i.e. from water) or by vibration, voltage overload, or short circuiting.

Symptoms of a Faulty Module

Since ECMs, TCMs, and PCMs have such far-reaching control, there is a vast range of effects of a broken module. Many of these affect overall vehicle function.

The engine may not start at all or the engine may run inconsistently (stuttering, coughing, misfiring, or stalling). Error lights on the dashboard may illuminate, which can give you a clue as to what the root cause of the problem is.

The transmission may not shift as it should (shifts may feel uncomfortably rough or happen at inappropriate times) and there could be a delayed response when the gas pedal is depressed. These problems indicate a problem with the TCM in older vehicles that have one.

Fuel economy or emissions may be poor. Sometimes these issues are first seen when a vehicle goes in for routine emissions testing.

Because the issues can mimic those caused by a variety of mechanical components, it’s difficult to diagnose the exact problem and electronics are often deemed the cause of a problem only after all other possibilities have been exhausted.

If the vehicle was made after 1995, use an OBD2 reader to check for codes and then troubleshoot to ensure there isn’t a problem other than the modules. The vehicle manual can help you with this, as you will want to examine all of the sensors thoroughly.

Sometimes a faulty PCM will throw a code for a given component when there isn’t actually an issue with that component at all but something like code P2509 should not be ignored.

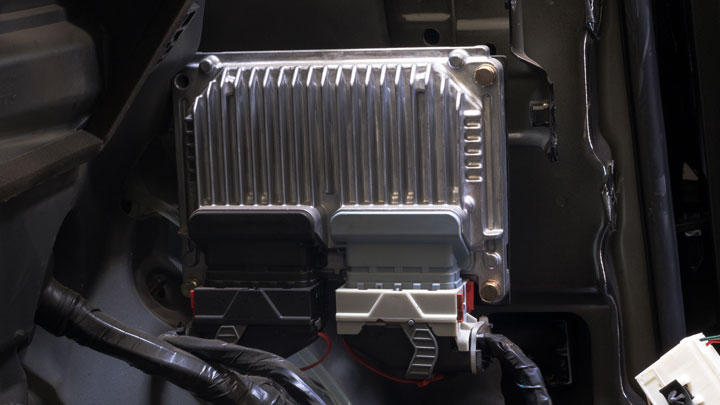

Replacing a Faulty Module

Once the ECM, TCM, or PCM has been isolated as the problem, check first to make sure that it doesn’t simply need an update. Computers need regular updates as the programming is improved by the manufacturer, so an update may solve the problem you’re having.

If the module is up to date but still not working, find an OEM (original equipment manufacturer) unit to replace it with. Aftermarket modules, though usually cheaper, may not work since the manufacturer has exact software the vehicle needs to perform well and this is difficult to replicate.

In fact, some auto manufacturers will do things to discourage aftermarket replacement, such as cause a problem that can only be cleared by a special manufacturer code. If you have a newer vehicle, replacing a module with anything but the OEM unit may void the manufacturer’s powertrain warranty.

Installing the new module is usually relatively simple as long as it can be easily accessed. Before removing the old module, disconnect the battery first.

This way if you find that the module is not actually the problem (i.e. if the new module doesn’t fix the problem) then the old module hasn’t been damaged by having the battery connected as the module was removed. Follow the vehicle manual for further instructions.

My vehicle is a 2003 BMW 745 li, and the problem is it will not start!! I’m get error messages that the TCM is malfunctioning. I’m trying to figure out where the TCM is located. Is it in the transmission or not? And how do I test it before ordering a new one?

Thanks

Grab a factory service manual. It will have all the information you are looking for.