Last Updated on April 4, 2022

The typical vehicle can be plagued by a number of mechanical issues throughout its lifespan, some of which tend to be more severe in nature than others. Understanding how to diagnose and repair such issues can serve as the difference between a minor hiccup, and substantial frustration.

One common, yet often misunderstood, of all mechanical issues is the standard vacuum leak. Depending upon its severity, a vacuum leak can be accompanied by a host of additional symptoms. Unfortunately, a number of these symptoms can prove detrimental to a vehicle’s overall drivability.

The first step to rectifying a vehicle’s vacuum leak is to recognize any number of the symptoms alluded to above. After identifying the issue at hand, a proper repair can commence, thereby expediting the process of returning your vehicle to service.

Read on to learn more about the various symptoms of a vacuum leak, as well as how to remedy such issues, should they be encountered in the future.

What Is a Vacuum Leak?

A vacuum leak is most easily described as the unintended introduction of unmetered air into an engine’s intake, by way of one or more compromised hoses, gaskets, or components.

This unmetered air is problematic, due to its tendency to upset an engine’s predetermined air-to-fuel ratio, thereby hindering combustion. However, to better understand the ramifications of a vacuum leak, one must first familiarize themselves with the principle of engine vacuum as a whole.

Vacuum, or negative pressure, is created within an engine, as each piston travels downward following combustion, during the intake stroke. This essentially creates a suction, which pulls incoming air into each respective cylinder, through open intake valves.

The amount of air introduced into each cylinder is metered by an engine’s throttle body. This component features a butterfly that opens and closes with respect to system demands, thereby increasing or decreasing the rate of air available for combustion.

However, the efficiency of this metering is negated, when an intake system leaks downstream of the throttle body, allowing unmetered air into the intake tract itself. This, in turn, disrupts an engine’s predetermined air-to-fuel ratio, which has the tendency to cause a host of drivability-related symptoms.

What Does It Sound Like?

In certain cases, a vacuum leak can actually be heard, thereby expediting the diagnostic process. However, as a general rule, substantial leaks are much easier to locate in this manner, than leaks of relative minor severity.

A vacuum leak often presents a light whistling or hissing noise, much like that heard when operating a shop-vac in confined quarters.

Though the location of this sound is generally difficult to pinpoint, many mechanics increase their odds at success by turning their ear to a vehicle’s engine compartment, while moving slowly from one side of the engine to the next.

Here’s an example of what a vacuum leak sounds like:

Symptoms of a Vacuum Leak

A vacuum leak can be accompanied by a wide range of symptoms. Some of these symptoms prove detrimental to a vehicle’s overall drivability, while others are more superficial in nature.

Nonetheless, recognizing the many symptoms associated with a vacuum leak can prove quite beneficial when attempting to remedy the issue at hand. The following are several of the most common symptoms associated with engine vacuum leaks.

#1 – Check Engine Light

In almost every instance, a vacuum leak will trigger an accompanying check engine light. The appearance of this check engine light signifies that a diagnostic fault code has been stored, in response to one or more operational issues.

In the case of a vacuum leak, an engine’s PCM/ECM has established that an engine’s fuel trims have begun trending in a positive, or lean direction. P0171 and P0174 are two common trouble codes related to vacuum leaks.

Related: How to Reset a Check Engine Light

#2 – Erratic Idling

Vacuum leaks often cause an engine to idle erratically, which is most often observed in the form of a higher than normal idle. Additionally, a vehicle’s tachometer might also appear to fluctuate at idle, differing as much as 300-400 RPM within a period of seconds.

In the majority of cases, this particular symptom is most prevalent when a severe vacuum leak exists.

#3 – Hesitation or Stalling

In the worst of cases, a vacuum leak can actually cause an engine to hesitate, or stall completely. This is due to the fact that an engine’s predetermined air-to-fuel ratio is compromised, whenever unmetered air is introduced into the intake tract.

Unfortunately, this symptom is not only hazardous but also potentially dangerous as well, depending upon the setting in which a stall takes place.

#4 – Rough Engine Operation

Outside of tell-tale hesitation or stalling, a sizable vacuum leak can also cause an engine to misfire or backfire.

This, again, is due to the fact that unmetered air is entering an engine’s intake manifold, thereby negatively impacting a vehicle’s predetermined air to fuel ratio. This almost exclusively manifests in the form of a noticeably lean condition.

#5 – Strange Engine Noises

Vacuum leaks are often accompanied by a strange squealing, whistling, or hissing sound. This sound is created when air is pulled through small cracks in an engine’s intake gasket or vacuum hoses.

Luckily, this symptom often proves valuable when attempting to locate the vacuum leak in question. One can simply listen for the source of this whistling or hissing, to isolate a leak to a particular portion of a vehicle’s engine bay.

Common Causes of a Vacuum Leak

An engine’s vacuum leak can be caused by a number of underlying factors, some of which tend to be far more severe in nature than others. A firm understanding of these underlying issues is of unparalleled value when attempting to make any necessary repairs.

The following are several of the most common causes of engine vacuum leaks.

#1 – Dry-Rotted Vacuum Hoses

Dry-rotted vacuum hoses are among the most common sources of an engine’s vacuum leak. With time, these hoses become dry and brittle, due largely to persistent exposure to heat and vibration.

Eventually, hair-line cracks begin to develop, all of which are capable of delivering unmetered air to an engine’s intake manifold.

#2 – Damaged Intake Hose

Most vehicles feature a plastic intake hose, which connects the air filter housing to the engine’s throttle body. Unfortunately, these tubes do get brittle with time, due to constant heat exposure.

These intake tubes are also commonly disturbed during air filter element replacement. The only way to remedy such issues is to replace the damaged hose in question.

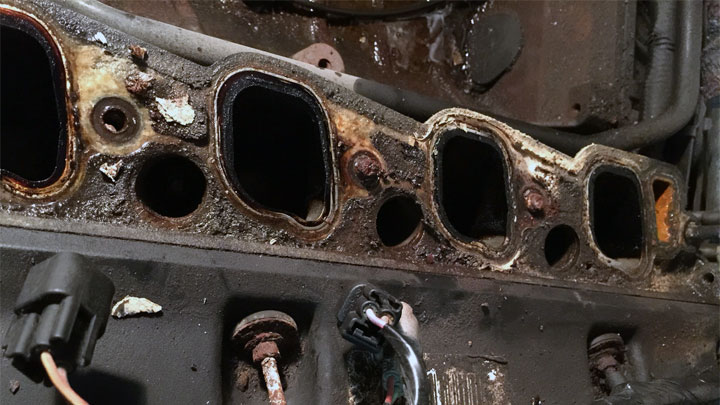

#3 – Leaking Intake Manifold Gasket

With time and age, an engine’s intake manifold can become compromised. When this occurs, outside air is pulled from beneath a vehicle’s hood, into an engine’s intake manifold, with no regard for metering.

This creates a lean condition on one or both of an engine’s banks, thereby impacting a vehicle’s drivability. Unfortunately, the repair is not always easy, nor cheap.

#4 – Cracked Intake Manifold

In rare instances, an engine’s intake manifold can actually crack, letting air flow freely through any open intake valves. This most often occurs as the result of engine overheating, though an intake manifold can also fail due to subpar casting procedures.

When such a failure occurs, replacement is often expensive, as well as quite time-consuming.

#5 – Stuck EGR Valve

An EGR valve is an integral part of a vehicle’s emissions system. This valve allows exhaust gasses to be fed into an engine’s intake manifold for further combustion. However, this reintroduction of exhaust gasses only takes place at specified times.

If the EGR valve becomes stuck due to carbon fouling, a vacuum leak will be created, allowing misrouted exhaust gasses to enter the intake.

#6 – Leaking Brake Booster Diaphragm

The vast majority of vehicle brake boosters are connected to an engine’s intake manifold, via one or more vacuum lines. A diaphragm within this assembly utilizes an intake vacuum to provide brake assist, as specified.

However, any rupture within this diaphragm will cause a substantial vacuum leak. A vehicle’s power-assisted brakes will also be compromised, leading to a dangerous situation.

#7 – Compromised PCV Valve or Hose

A vehicle’s PCV valve (positive crankcase ventilation) removes excess combustion gasses from an engine’s crankcase, reintroducing them into an engine’s intake for further combustion.

However, these valves or their accompanying hoses do tend to fail with age, creating a substantial vacuum leak. When this occurs, replacement is necessitated.

Is It Okay to Drive With a Vacuum Leak?

It is considered best practice to drive a vehicle with an obvious vacuum leak, no greater distance than absolutely necessary.

In a “best case” scenario, driving a vehicle with a defined vacuum leak can present a number of drivability-related issues, such as erratic idle, reduced performance, and even stalling. However, the “worst case” scenario is much more dire.

An engine can become damaged if operated for extended periods of time with a severe vacuum leak. This is due to the fact that a lean air-to-fuel ratio, caused by a vacuum leak can increase heat within an engine’s combustion chambers. As such, damage to an engine’s pistons and exhaust valves often results.

In any event, the source of a particular vacuum leak should be diagnosed and remedied as soon as possible. This greatly reduces the chance of resulting engine damage.

If you do not feel comfortable tackling such repairs yourself, make an appointment with a trusted service center at the first available opportunity.

Can I Fix a Vacuum Leak Myself?

You can indeed fix a vacuum leak yourself. However, doing so requires one to locate the source of the leak itself. This procedure alone can prove quite complex, depending upon the severity of the leak in question. Once the source of an engine’s vacuum leak has been uncovered, a plan for proper repair can be hatched.

By nature, some vacuum leaks tend to be more difficult to repair than others. This stems from the fact that the source of a vacuum leak can range from a dry-rotted hose to a compromised intake gasket. While the first of these issues can be repaired in minutes, the latter often takes hours and is far more involved.