Last Updated on November 14, 2022

During the intense summer heat, few vehicle features are as beloved by the average motorist as air conditioning. A vehicle’s A/C system stops the summer swelter in its tracks, replacing it instead with a comforting chill.

Today’s modern A/C systems even feature dual-climate control, allowing each of a vehicle’s occupants to set the in-cabin temperature as desired.

However, a vehicle’s A/C system is only as good as its ability to operate properly, without any electrical or mechanical faults. Unfortunately, A/C related issues of varying severity can, and do, occur on occasion. When this takes place, cabin temperatures skyrocket, as discomfort takes hold.

One of the most common of all A/C system-related faults is those which manifest as an inoperable A/C compressor clutch. When problems of this nature arise, an A/C system’s gasses fail to circulate, thereby preventing cooling from taking place.

Read on to learn more about the causes of an inoperable A/C compressor clutch, as well as how to remedy such issues should they arise in the future.

See Also: 8 Reasons Your A/C Is Not Blowing Cold Air

What Is an A/C Compressor Clutch?

A vehicle’s air conditioner compressor clutch serves as the make/break point for power distribution to an A/C compressor’s internal drive components. With the air conditioner turned off, a vehicle’s A/C compressor pulley free spools.

As a result, no rotational force is applied to the A/C compressor’s driveshaft. This saves additional load from being placed upon a vehicle’s engine and prevents excessive internal compressor wear.

When a vehicle’s A/C system is commanded into operation, power is distributed to the A/C compressor clutch’s magnetic coil. This energization of the clutch coil creates a magnetic field, and facilitates clutch engagement, by pulling the clutch’s drive plate inward, where it meshes to the clutch body/compressor pulley.

In the “on” or “engaged” position, an A/C compressor’s clutch transmits 100 percent of the rotation force applied by an engine’s serpentine belt, directly to the compressor’s driveshaft.

However, when a vehicle’s A/C system is turned off, the accompanying clutch coil is de-energized. In turn, the A/C system clutch disengages.

Related: Symptoms of a Bad Car A/C Condenser

Causes of an A/C Compressor Clutch That Won’t Engage

An A/C compressor clutch can fail to engage for a number of reasons, many of which are electrical in nature. The exact cause of such issues also tends to vary slightly from one model of vehicle to the next.

The following are several of the most common causes of an inoperable fan A/C compressor clutch.

#1 – Blown A/C Clutch Fuse

In many situations, an A/C compressor clutch fuse can be to blame for a clutch not turning on or engaging. However, one must also determine the reason behind the fuse’s failure. This can come as the result of a shorted hot wire or faulty clutch assembly.

#2 – A/C Clutch Relay Failure

Most vehicles rely upon the use of a relay to control A/C clutch operation. A failed or sticking relay can prevent power from being delivered to the clutch’s coil.

#3 – Faulty Switches

Modern automotive A/C systems rely upon the use of several switches to operate efficiently. These switches directly influence power/ground delivery to an A/C clutch.

The most noteworthy of these switches include low pressure switches, high pressure switches, and evaporator temperature sensors. The failure of any of these sensors can render an A/C clutch inoperable.

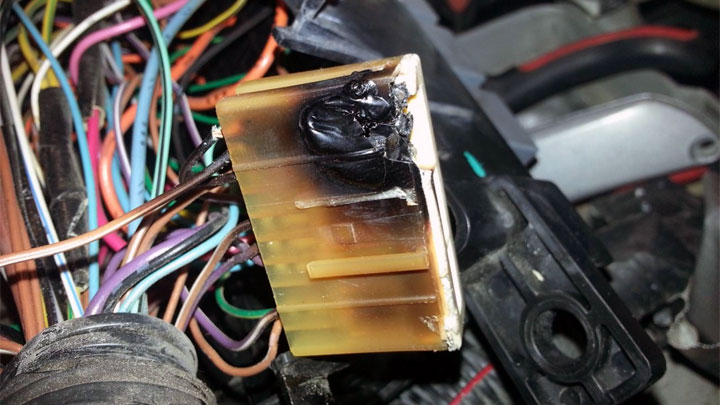

#4 – Faulty Wiring

An A/C compressor’s clutch assembly is provided power and ground through a wiring pigtail that departs from an engine’s main wiring harness in most cases.

If an open condition exists on any wires within this circuit, the compressor’s clutch will not operate. In some cases, the wiring may be fine but the harness is the problem.

#5 – Low Refrigerant Charge

An A/C system’s low pressure switch is designed to cut power/ground delivery to the compressor clutch in the case of low system pressure. Therefore, a lack of compressor clutch operation can often be traced back to a low refrigerant amount where a freon recharge is necessary.

#6 – High Refrigerant Charge

Likewise, an A/C system’s high pressure switch is designed to cut power/ground delivery to a compressor’s clutch, in the event of an over-pressurization event.

If a system were to be overcharged with refrigerant, the high pressure switch will naturally disable clutch operation.

#7 – Faulty A/C Clutch

With time, a compressor’s clutch assembly can begin to show its age. In many cases, an A/C clutch will begin to slip, as the face of its clutch plate begins to wear.

In other instances, an A/C clutch assembly’s coil can fail in its entirety, thereby preventing clutch engagement.

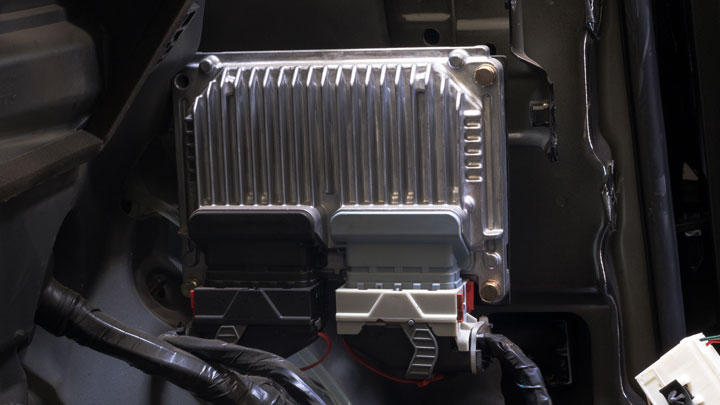

#8 – Control Head/Computer Failure

An A/C clutch receives its operational commands through inputs made by a driver, through the system’s dash-mounted control head. Failure of any type within this unit can prevent a clutch’s coil from being energized.

Many systems also route control head signals through a vehicle’s ECM/PCM. Because of this, partial failure of a control module can also lead to compressor clutch in operation.

How to Manually Engage an A/C Compressor Clutch

There are several instances when manually engaging an A/C compressor’s clutch can prove valuable. Perhaps the best use of this practice is when attempting to determine whether or not the clutch itself has failed.

Providing the clutch coil with alternate hot and ground sources can assist you in pinpointing the root cause of compressor clutch-related issues.

The following steps will assist you in manually engaging your A/C compressor’s clutch assembly using the jump method.

- Disconnect Clutch Wiring Pigtail: You must first identify and disconnect the wiring pigtail that corresponds to your compressor’s clutch assembly. The wiring for this assembly typically originates from behind the A/C, at the front end of a vehicle’s compressor.

- Identify Power and Ground Wires: Next, you must identify the power and ground pins within this connector. When in doubt, always consult a factory wiring diagram for your specific vehicle.

- Fashion Jumper Wires: You will now fashion jumper wires for both the power and ground ends of your compressor’s control circuit. It is important to include an inline fuse in the jumper wire intended for use on the positive side of the circuit. It is also helpful to affix alligator clips to the supply end of these jumper wires, which can be easily connected to your battery’s terminals.

- Hook Up Jumper Wires: It will now be time to hook up your newly fashioned jumper wires. Ensure that the fused jumper wire is connected between your clutch coil’s positive wire and your battery’s positive post. Likewise, hook the remaining jumper wire between the clutch coil’s negative wire and your battery’s negative post.

- Interpret Results: Based upon your observations, you will now be able to determine whether or not your A/C clutch is bad. If your compressor’s clutch fails to engage when jumped, compressor replacement is advised. Engagement will be evident by the sudden rearward movement of the assembly’s clutch plate, which will be accompanied by an audible “click”. If your A/C compressor’s clutch engages when jumped, further diagnosis will be required, as the underlying fault resides in the system’s control circuit.

Replacing the A/C Compressor Clutch vs A/C Compressor

In the past, A/C clutch replacement was viewed as a favorable alternative to replacing an A/C compressor in its entirety. However, this is seldom the case today. Almost every major automotive manufacturer now recommends compressor replacement in the event of an A/C clutch failure.

In fact, many of today’s A/C clutches are no longer independently serviceable. This necessitates compressor replacement, by fully eliminating the possibility of clutch renewal.

Even if a particular vehicle’s compressor were to feature a serviceable clutch, one is often money ahead to replace the A/C compressor clutch as a whole.

Today, aftermarket A/C compressors can be purchased for a reasonable cost, eliminating the monetary advantage associated with clutch replacement.

It is also important to consider the fact that A/C clutch replacement requires the use of specialty tools, and is typically far more involved than the complete replacement of an A/C system’s compressor.

Read Also: Symptoms of a Bad A/C Expansion Valve

Thank you for sharing. I learned how to use the jump method to manually engage the ac compressor clutch assembly.

I seen a mechanic use hammer to knock on the compressor clutch and it got the ac working again, is this bad for the ac compressor and will it cause ac compressor to fail eventually?

I’d say if the mechanic has to use that trick to get the compressor working again, there’s something else wrong with the A/C that should be fixed.

I have just changed the bad bearing of the compressor that caused the noise when running, it was fixed but the problem came out that the clutch does not engage, how do I fix this problem?